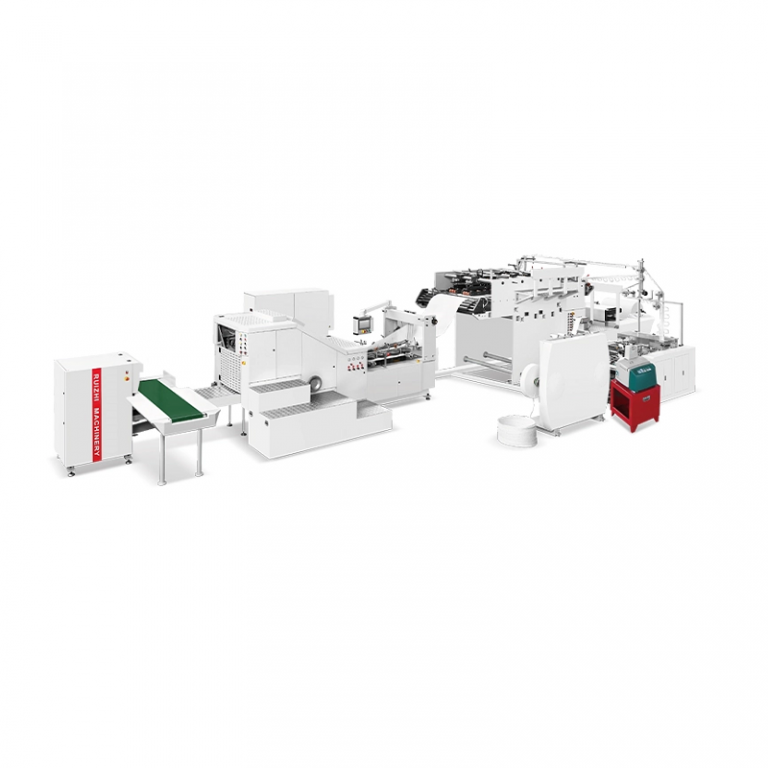

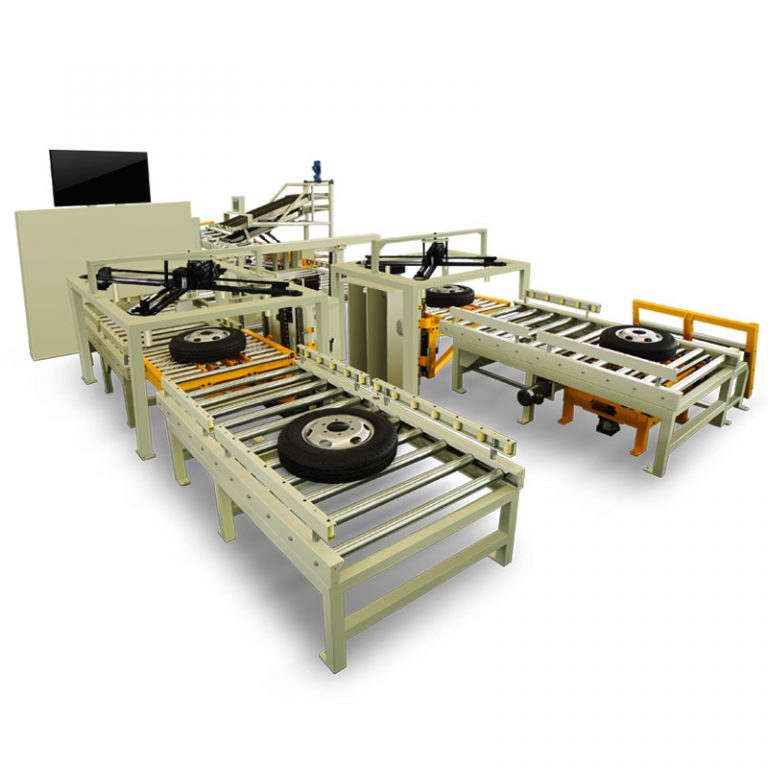

We specialize in manufacturing

What is hydraulic torque wrench?

What is hydraulic torque wrench? A hydraulic torque wrench is a specialized tool used to apply a precise amount of torque to a fastener, such as bolts or nuts, via a hydraulic system. This type of wrench is particularly useful in industrial applications where high torque levels are required, such as in construction, manufacturing, and maintenance of heavy machinery, pipelines, and structural components. Key Features of Hydraulic Torque Wrenches: 1. Hydraulic Power: The wrench uses hydraulic fluid to multiply force, allowing it to exert a higher torque without requiring excessive manual effort. 2. Precision: Hydraulic torque wrenches typically provide very accurate torque settings, making them suitable for applications where correct torque is critical to the integrity of a joint. 3. Speed: These wrenches can often operate faster than mechanical torque wrenches, increasing efficiency in tasks that involve multiple fasteners. 4. Versatility: Hydraulic torque wrenches come in various sizes and configurations (such as low-profile designs) to accommodate different types of fasteners and working environments. 5. Safety: Many hydraulic torque wrenches are designed with safety features to minimize the risk of injury,

What is high temperature bearing?

What is high temperature bearing? High temperature bearings are specially designed bearings that can operate effectively in elevated temperature environments, typically over 150°C (302°F) and sometimes up to 300°C (572°F) or higher. These bearings are engineered to withstand the thermal stress, lubrication challenges, and material degradation that occur at high temperatures. Key Features of High Temperature Bearings: 1. Material Composition: High-temperature bearings are often made from specialized materials such as ceramics, high-temperature alloys, or polymers that can withstand thermal expansion and maintain their mechanical properties at elevated temperatures. 2. Lubrication: Standard lubricants may break down at high temperatures, so high-temperature bearings often use specialized lubricants that remain stable and effective under extreme conditions. Solid lubricants, such as graphite or certain types of ceramic-based lubricants, can also be used. 3. Design: These bearings may have modified designs, including seals and coatings that help retain lubrication and reduce wear and tear. 4. Applications: High-temperature bearings are commonly used in environments such as steel mills, ceramic processing, high-temperature ovens, aerospace applications, and various industrial machinery where elevated temperatures are present. 5. Thermal Conductivity: