We specialize in manufacturing

What is Horizontal Dough Mixer?

What is Horizontal Dough Mixer? A Horizontal Dough Mixer is a type of industrial mixing equipment designed to combine ingredients for dough production efficiently. It features a horizontally oriented mixing chamber, typically equipped with a rotating agitator or blades that uniformly mix flour, water, yeast, and other ingredients to produce dough for bread, pastries, and other baked goods. Key features of a Horizontal Dough Mixer include:-Horizontal orientation:The mixing drum is positioned horizontally, which helps in thorough mixing and kneading.-Agitator or blades:These rotate to knead the dough, mimicking manual kneading but with increased efficiency.-Capacity:Available in various sizes, suitable for small bakeries or large industrial bakeries.-Efficiency:Provides consistent mixing, better dough development, and reduced mixing time compared to manual methods. Horizontal dough mixers are favored in commercial baking environments for their ability to produce uniform dough batches with minimal manual effort, ensuring high-quality baked products.

What kind of high temperature bearings are better for the steel and metal production industry?

What kind of high temperature bearings are better for the steel and metal production industry? In the steel and metal production industry, high-temperature bearings are critical components that must withstand extreme operational conditions, including high temperatures, heavy loads, and sometimes corrosive environments. The most suitable types of high-temperature bearings for these applications typically include: 1. Ceramic Bearings:- Silicon Nitride (Si₃N₄) Bearings: Known for excellent thermal stability, corrosion resistance, and low thermal expansion. They can operate at temperatures up to 1,200°C (2,192°F) and are ideal for high-speed and high-temperature environments.- Advantages: Reduced weight, high hardness, and electrical insulation properties. 2. High-Temperature Alloy Bearings:- Inconel or other Nickel-Based Alloy Bearings: These are used in applications where ceramic bearings may not be suitable. They can withstand temperatures up to approximately 950°C (1,742°F).- Advantages: Good mechanical strength and corrosion resistance at high temperatures. 3. Self-Aligning and Spherical Roller Bearings with Special Heat-Resistant Materials:- Made with heat-resistant steels or composites, designed to operate in high-temperature zones.- Often used in rolling mill equipment, furnace rollers, or continuous casting machines. 4. Specialized Coatings and Lubricants:- Use of

What is Electric Pruning Shear?

What is Electric Pruning Shear? An Electric Pruning Shear is a gardening tool designed for cutting branches and stems. Unlike manual pruners that rely on the user's hand strength, electric pruners use a power source (typically a rechargeable battery) to drive a moving blade, making the cutting process significantly easier and less strenuous. Think of it as a highly specialized, compact electric saw or pair of scissors specifically for plant material. Key Components and How It Works 1. Blades: Usually made of high-carbon steel or titanium-coated steel for durability and a sharp edge. One blade is stationary, while the other is the moving blade that does the cutting.2. Power Source: Most modern electric pruners are cordless, powered by a rechargeable lithium-ion battery (often the same type used for power tools, like 20V Max packs). Some older or heavy-duty professional models might be electric corded or even pneumatic (air-powered).3. Motor: A small but powerful electric motor converts battery power into the cutting motion. This can be a straight reciprocating (back-and-forth) motion or a rotating motion that drives the mechanism.4. Activation Mechanism:

What is High Temperature Ceramic Bearing?

What is High Temperature Ceramic Bearing? A High Temperature Ceramic Bearing is a type of bearing designed to operate efficiently and reliably at elevated temperatures, often significantly higher than standard steel bearings. These bearings typically utilize ceramic materials such as silicon nitride (Si₃N₄), zirconia (ZrO₂), or alumina (Al₂O₃) for their rolling elements (balls or rollers) and sometimes for the races. Key Features of High Temperature Ceramic Bearings: 1. Material Composition:- Ceramic Components: The rolling elements and sometimes the races are made from advanced ceramics known for their high thermal stability, hardness, and wear resistance. - Metal Components: The cages, seals, or other structural parts may be made from high-temperature plastics, stainless steel, or other heat-resistant materials. 2. High Temperature Resistance:- These bearings can operate at temperatures ranging from approximately 200°C up to 1000°C or more, depending on the specific materials and design. 3. Advantages:- Reduced Thermal Expansion: Ceramic materials have lower coefficients of thermal expansion compared to metals, maintaining tighter tolerances at high temperatures. -Corrosion and Oxidation Resistance: They are less susceptible to oxidation and corrosion in harsh environments. -

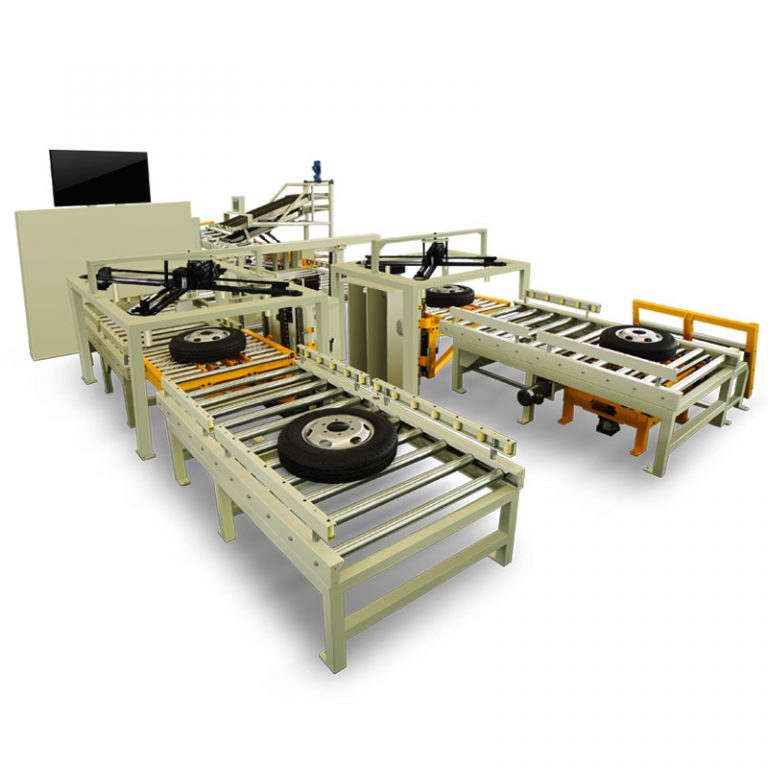

What is Four-station Magneto Rotor Automatic Balancer?

What is Four-station Magneto Rotor Automatic Balancer? A Four-Station Magneto Rotor Automatic Balancer is a specialized device used to ensure the proper dynamic balancing of magneto rotors, which are critical components in ignition systems of engines such as aircraft or small engines. Proper balancing of rotors is essential to prevent vibrations, reduce wear, and enhance the lifespan and performance of the engine. Key Features and Functions: 1. Four-Station Balancing:The device supports balancing at four different stations or points around the rotor's circumference. This multi-point approach allows for more precise detection and correction of imbalance, ensuring the rotor spins smoothly. 2. Magneto Rotor Compatibility:Designed specifically for magneto rotors, which are often made of lightweight materials and have intricate magnetic components, requiring careful balancing to avoid operational issues. 3. Automatic Balancing Mechanism:Equipped with sensors, electronic controls, and actuators that automatically detect imbalance and apply corrective measures, such as adding or removing small weights or adjusting mass distribution, without manual intervention. 4. Magnetic or Electromagnetic Components:The "magneto" aspect indicates the use of magnetic or electromagnetic technology in the balancing process, possibly involving magnetic

What are the types of high temperature bearings?

What are the types of high temperature bearings? High-temperature bearings are designed to operate efficiently under elevated temperature conditions, often found in industries such as aerospace, automotive, manufacturing, and energy. The primary types of high-temperature bearings include: 1. Ball Bearings:Ceramic Ball Bearings: Use ceramic (usually silicon nitride) balls that can withstand higher temperatures and offer lower thermal expansion, reduced friction, and better wear resistance compared to steel balls.High-Temperature Steel Ball Bearings: Made from special alloys like stainless steel or heat-treated steels designed for elevated temperatures. 2. Roller Bearings:Cylindrical Roller Bearings: Suitable for high load capacities and can be made with heat-treated steels for higher temperature tolerance.Spherical Roller Bearings: Designed to handle misalignment and heavy loads, with materials chosen for high-temperature applications.Tapered Roller Bearings: Used in applications requiring high load and speed, with high-temperature variants. 3. Plain Bearings (Thrust and Journal Bearings):Graphite Bearings: Use graphite materials capable of operating at very high temperatures.Copper and Bronze Bearings: Often used in high-temperature environments due to their thermal stability.Ceramic Bearings: Some plain bearing surfaces incorporate ceramic composites for high-temperature endurance. 4. Specialized High-Temperature Bearings:Ceramic

What is cross flow fan assembly balancers?

What is cross flow fan assembly balancer? A cross flow fan assembly balancer is a diagnostic and adjustment device used to ensure the proper balance of a cross flow fan assembly. Cross flow fans, also known as tangential fans, are characterized by a long, rectangular duct with an impeller mounted perpendicular to the airflow direction. They are commonly used in applications like air conditioning units, ventilation systems, and cooling equipment due to their uniform airflow distribution. The purpose of a balancer in this context is to detect and correct any imbalances in the fan assembly caused by uneven mass distribution, manufacturing imperfections, or accumulated debris. An unbalanced fan can lead to vibrations, noise, reduced efficiency, and premature wear of components. Key functions of a cross flow fan assembly balancer include:Measuring imbalance:It detects the magnitude and location of imbalance by analyzing vibrations or dynamic forces as the fan operates.Providing correction data:It guides technicians on how to add or remove weight (such as balancing weights) to specific areas of the fan assembly.Ensuring smooth operation:Proper balancing minimizes vibrations and noise, prolonging the lifespan

What industries are suitable for high temperature bearings?

What industries are suitable for high temperature bearings? High temperature bearings are essential components in a variety of industries where machinery operates under extreme heat conditions. Here are some of the key industries that commonly utilize high temperature bearings: Steel and Metal Production: Furnaces, rolling mills, continuous casting machines, and other equipment in steel and metal manufacturing operate at extremely high temperatures. Bearings in these environments must withstand radiant heat, direct contact with hot materials, and often heavy loads. Glass Manufacturing: Glass furnaces, lehrs (annealing ovens), and forming machinery involve processes that reach very high temperatures. Bearings in these applications need to maintain their structural integrity and lubrication properties in these harsh thermal environments. Cement and Lime Production: Kilns and grinding mills in cement and lime plants operate at high temperatures. Bearings are used in conveyors, crushers, and rotating equipment that handle hot materials. Ceramics and Brick Manufacturing:Similar to glass and cement, the firing processes in ceramic and brick production involve high temperatures. Bearings are needed in kilns, conveyors, and other handling equipment. Food Processing:While not always as

What is high shear emulsifier mixer?

What is high shear emulsifier mixer? A high shear emulsifier mixer is a specialized piece of equipment used in various industries, such as food production, pharmaceuticals, cosmetics, and chemicals, to create stable emulsions, suspensions, and homogenized mixtures. The primary function of a high shear emulsifier is to rapidly mix and blend ingredients at high speeds, effectively reducing particle size and improving the uniformity of the mixture. Key Features of High Shear Emulsifier Mixers: 1. High Shear Mechanism: These mixers use high-speed rotating blades or rotors to create intense shear forces. This process breaks down and disperses the ingredients into smaller particles, leading to a uniform emulsion. 2. Emulsion Formation: High shear emulsifiers are capable of producing both oil-in-water (O/W) or water-in-oil (W/O) emulsions, depending on the formulation and process conditions. 3. Versatility: They can be used to mix a wide range of materials, including liquids, viscous fluids, and powders, making them versatile for various applications. 4. Efficiency: The high shear mixing process is often faster than traditional mixing methods, leading to significant reductions in processing time. 5. Consistent Quality: The

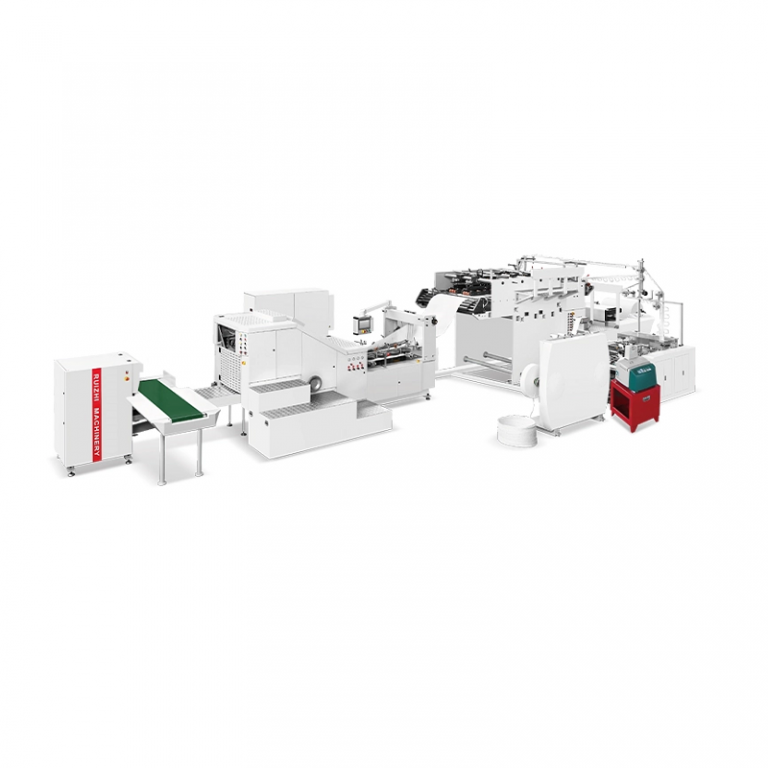

What is paper bag machine?

What is paper bag machine? A paper bag machine is a type of industrial equipment designed to manufacture paper bags from rolls of paper. These machines automate the process of converting flat paper into finished bags, making them suitable for various applications such as retail shopping, packaging, food service, and more. The basic operation of a paper bag machine typically includes several stages: 1. Feeding: Rolls of paper are fed into the machine.2. Printing(optional): If branding or designs are needed, the paper may go through a printing process.3. Cutting: The paper is cut into specific lengths to create the bag body.4. Folding and Gluing: The cut paper is folded and glue is applied to form the bottom and sides of the bag.5. Bottom Formation: The bottom of the bag is formed, often involving folding and compression to create a sturdy base.6. Final Output: The finished bags are ejected from the machine and collected for packaging or further processing. There are various types of paper bag machines, including those that can produce flat bags, square-bottom bags, and more complex designs. Depending